Stable & Reliable Continuous Operation

Designed for continuous operation in food and beverage production, ensuring long-term stable monitoring of critical process parameters.

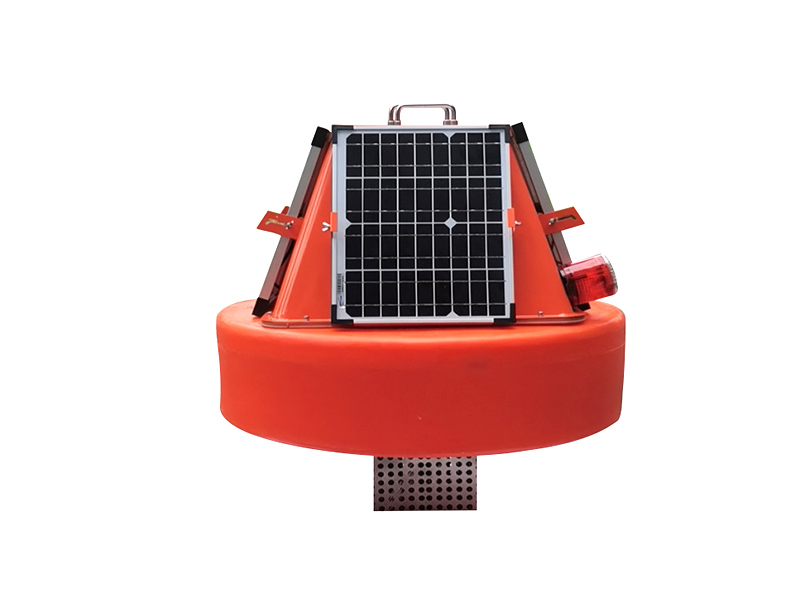

Food and beverage production requires stable and continuous monitoring across multiple process stages. Wohuan’s instruments and monitoring systems support production, transfer, and cleaning processes, ensuring controlled operation and consistent product quality.

Designed for continuous operation in food and beverage production, ensuring long-term stable monitoring of critical process parameters.

Stable process monitoring helps maintain controlled production processes and supports consistent product quality management.

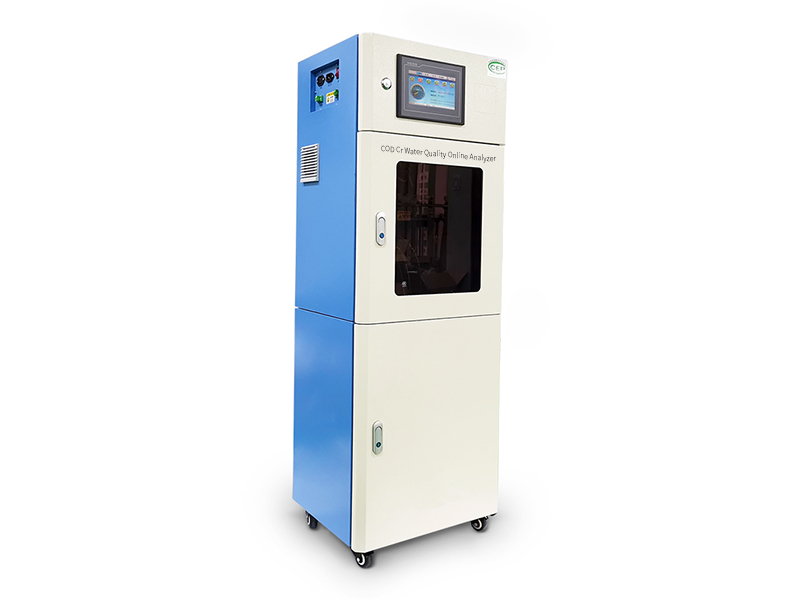

Solutions are suitable for both food and beverage production processes and CIP cleaning systems, meeting diverse operating requirements.

Feedback from food processing plants, beverage production lines, and food engineering projects reflects Wohuan’s stability, process adaptability, and long-term performance in food and beverage applications.

1️⃣ Deep Understanding of Food & Beverage Processes

2️⃣ Stable & Reliable Continuous Operation

3️⃣ Supports Quality Control & Production Consistency

Yes. Wohuan’s food and beverage solutions are designed for continuous production environments and are suitable for 24/7 operation with long-term stable monitoring of critical process parameters.

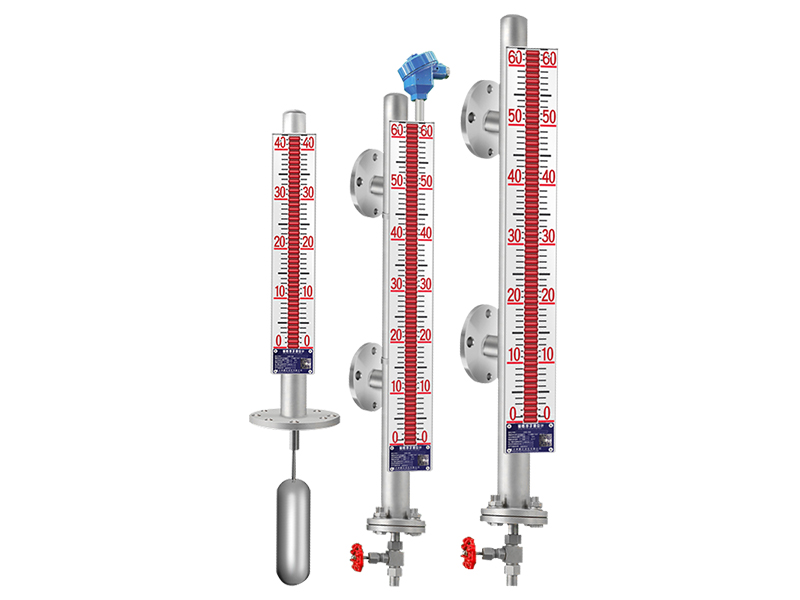

Common process parameters such as flow, pressure, level, and temperature can be monitored. Configurations can be adjusted according to specific food or beverage production processes.

Yes. The solutions are suitable for both production processes and CIP cleaning systems, meeting monitoring requirements during cleaning operations.

Yes. Products and systems are designed with integration in mind and can be integrated into existing control systems or monitoring platforms.

Yes. Solutions can be configured according to production scale and process requirements, suitable for both small production lines and large food and beverage plants.

The solutions are designed to adapt to complex food and beverage process conditions and maintain stable operation.

Yes. Project-level configuration is available based on process workflows and system requirements of food and beverage engineering projects.

We provide full technical support and service covering product selection, engineering implementation, and operation and maintenance.